Filtering APIs, raw materials, intermediates and excipients in small molecule and biological drugs

Although biologic drugs and small molecule are very different in nature, size and production, the filtration strategies for ensuring ultrapure APIs and excipients are very similar. Ingredients used in the production of these pharmaceuticals are mostly sourced by external companies. Often we see that these ingredients are treated like if they contain contaminants which possibly can harm the production process or the quality of the end product. The quality of the ingredients need to be checked to see if filtration is required or not.

The problem with theses outsourced ingredients is that we are unknown about the contamination which might be in there. Even if this is from a supplier which use the necessary filters and has a good reputation on their quality, we still need to know this for sure to be safe. If we want to avoid any problems with unwanted bacteria, particles or other contamination we need to set up an effective filter configuration to make sure the ingredients are clean from unwanted particles. This filter should be very cost effective since the product supposed to be clean already.

Filtration Goals

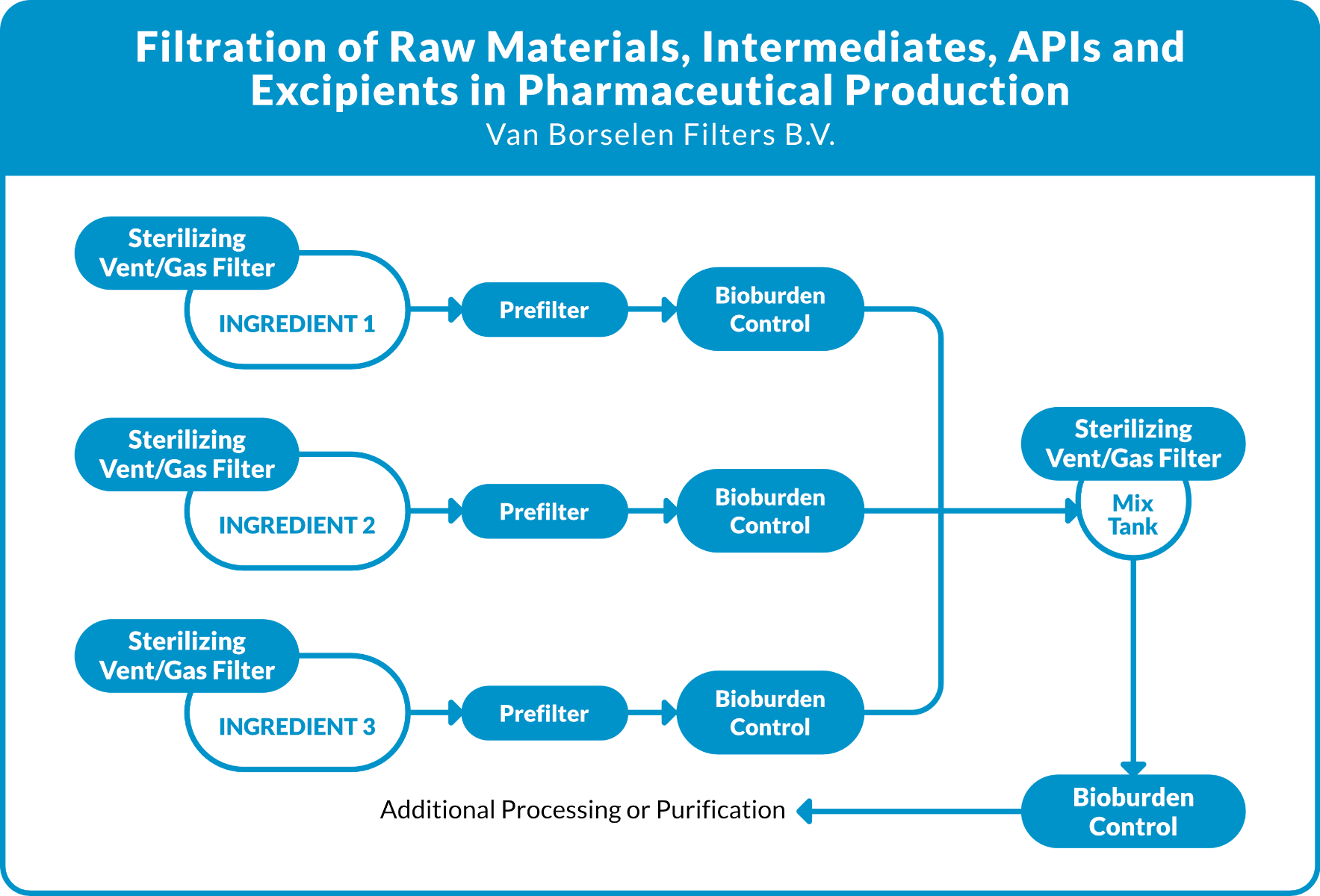

Ensuring the purity and quality of the ingredients as they will be add in the production process increases and improves the final product quality. The Schematic figure 1 highlights the filters that can be used as a prefilter before the it enters the production process. These filters are designed to remove microorganisms and particles and they will protect the product from environmental contamination while they are stored in the tanks.

The filters in figure 1 are performing the basic functions by removing all contaminants from the ingredients. The prefilter will remove the paticles, the bioburden filters will take care of the bacteria while the tank vent filter will make sure there is no contamination from outside the tank while the tanks breaths the enviromantal air. In some cases we need to install more or other type of filters depending on the ingredients, flows and type of unwanted particles or microorganisms.

Filters that will remove the particles.

Prefilters are the ideal filters to filter out unwanted bigger particles that may come out of the process line. At the point of entry for each ingredient we will use a prefilter. The prefilters are designed to take all larger particles that can foul the end filter or sterilizing filters which is next in line. Depending on the particle size distribution and load of particles additional prefilters can be used in serie to protect the final filter. It is possible to use multiple separate filters or to use a filter which is made from different filtration layers to capture the particles in depth. Depth filters are a well-known solution for this although pleated filters will have a larger surface area due to pleating the material. Because of these pleats there is more surface area which can remove more particle contaminants then a standard depth filter.

Filters that will remove or control bioburden.

Bioburden reduction filters or bioburden control filters are designed to remove most, not necessarily all, bacteria. The micron ratings varies from 0.22µm, 0.45µm up to 0.65µm which is depending on the organisms that need to be removed. These bioburden reduction filters are generally used to relief the final sterilizing filters.

Depending in the process you can choose to use sterilizing filters at the points marked in the diagram as controlling bioburden filters. Several factors need to be considered to make a choice:

- Probability of bacterial contamination in the ingredient.

- Level of possible contamination

- How conducive is the formulation to bacterial growth?

- Adequacy of cleaning/sterilisation procedures for the delivery and tank system.

- The load on downstream sterilisation filters if no bioburden reduction filter is used.

- Likelihood of bacterial contamination in the ingredient

- Level of contamination that might be encountered

- Adequacy of cleaning/sterilizing procedures for the delivery and tank system

- The burden placed on downstream sterilizing filters if a bioburden reduction filter is not employed

- How conducive is the formulation to bacterial growth?

If bacteria can easily multiply in the product, a sterilisation filter is the best choice. If not, a less expensive bioburden reduction filter can be used.

Sterilizing filters

Sterilizing grade filters are suitable for removing particles and bacteria with a size of 0.22 or 0.1µm. If necessary, they can be used in areas marked as bioburden control. A sterilizing grade filter is often used in the line from the mixing tank to further processing.

Van Borselen Filters sterilizing filters are validated for > 7-log bacteria removal according to ASTM-838-15. Van Borselen Filters provides a validation guide for the chosen filter(s) with test results for bacterial retention and information on filter construction, biosafety and performance. The final choice of pore size often requires validation testing in the actual liquid to be processed.

Vent and gas filters for tanks Vent filters are used to protect the product or buffer solutions stored in tanks from contamination by bacteria and particles. When a tank is filled, the air in the tank must be allowed to escape. However, when the tank is emptied, air or a gas must come into the tank to replace the liquid which is lost. The filter removes particles and bacteria from the air or gas to ensure the quality of the product. It is important that the membrane of the vent or tank filter stay dry to make sure the air or gas can pass through the filter. Mostly these filters are made from hydrophobic PTFE membrane.

Selecting the right filters

The right choice between prefilters and the sterilizing (bioburden) filters is important. The proper sequence will ensure an optimized efficient filtration process while minimizing the costs. Van Borselen Filters can help you determine which filters are the right choice for your process. Beside that we can help with testing in our lab or at your site.

The selected filter need to be checked on compatibility with the product and chemicals but also with the sterilization methods you use. The filters need to remove the organisms without and should not give any effect on the filtered product.

Van Borselen Filters can offer you different an multiple filtration option:

Membrane and media materials - PES, nylon 6.6, PVDF, PTFE, polypropylene, glass fibre.

Filter configurations - Cartridge, Capsule, Laboratory scale

Filter function - Sterilisation, bioburden reduction, pre-filters and more.

Options for prefilters

Options for bioburden reduction filters for liquids